Introduction to Process Manufacturing ERP

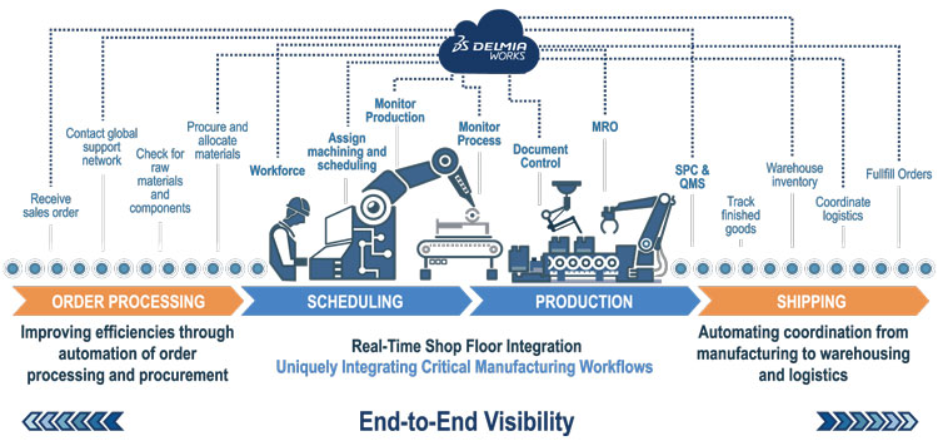

Insert image of a process manufacturing ERP system.

Process manufacturing ERP (Enterprise Resource Planning) systems are crucial for businesses involved in manufacturing processes where products are created through a continuous or batch process, such as chemicals, food and beverage, pharmaceuticals, and more. These systems integrate various functions such as inventory management, procurement, production planning, and compliance management into a single platform. By consolidating these operations, process manufacturing ERP systems enhance efficiency, reduce errors, and improve decision-making.

Key Benefits of Process Manufacturing ERP Systems

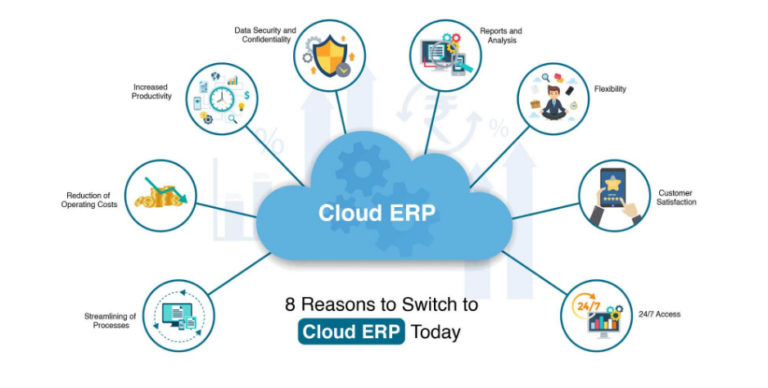

Insert image of process manufacturing ERP benefits.

Process manufacturing ERP systems offer numerous advantages:

- Enhanced Efficiency and Productivity: Automating routine tasks and integrating processes reduce manual errors and streamline operations, leading to increased productivity.

- Real-Time Data and Analytics: These systems provide real-time data on production, inventory, and procurement, allowing for better decision-making and forecasting.

- Regulatory Compliance: Ensuring compliance with industry regulations and standards is simplified through automated reporting and documentation features.

Leading Process Manufacturing ERP Products

1. SAP S/4HANA

Insert image of SAP S/4HANA.

SAP S/4HANA is a comprehensive ERP solution designed for various industries, including process manufacturing. It provides real-time analytics, a streamlined user experience, and advanced features tailored to the needs of process manufacturers.

Use Case: Ideal for large enterprises requiring robust, scalable solutions with extensive functionalities.

Pros:

- Real-time data processing and analytics.

- Integration with various business functions.

- Highly customizable.

Cons:

- High implementation cost.

- Complexity in customization.

Price: Contact SAP for pricing information.

Where to Buy: SAP S/4HANA – Visit SAP’s website to request a demo or get pricing details.

2. Oracle ERP Cloud

Insert image of Oracle ERP Cloud.

Oracle ERP Cloud offers a flexible and scalable ERP solution with strong process manufacturing capabilities. It features comprehensive financial management, supply chain planning, and advanced analytics.

Use Case: Suitable for medium to large-sized businesses looking for a cloud-based solution with extensive integration options.

Pros:

- Flexible deployment options (cloud-based).

- Extensive functionality and integration.

- Advanced analytics and reporting.

Cons:

- Can be expensive for smaller businesses.

- Implementation may require significant time and resources.

Price: Contact Oracle for pricing details.

Where to Buy: Oracle ERP Cloud – Visit Oracle’s website for more information and to schedule a demo.

3. Microsoft Dynamics 365

Insert image of Microsoft Dynamics 365.

Microsoft Dynamics 365 combines ERP and CRM functionalities into one platform, making it a versatile choice for process manufacturers. It provides advanced tools for managing operations, finance, and customer relationships.

Use Case: Ideal for businesses that need a unified solution integrating ERP and CRM functionalities.

Pros:

- Integration with Microsoft Office and other Microsoft products.

- Customizable and scalable.

- Strong support and user community.

Cons:

- May require additional customization.

- Potentially high costs depending on deployment and usage.

Price: Pricing varies based on the modules and number of users.

Where to Buy: Microsoft Dynamics 365 – Visit Microsoft’s website to learn more and request a quote.

4. Infor CloudSuite Process Manufacturing

Insert image of Infor CloudSuite Process Manufacturing.

Infor CloudSuite Process Manufacturing is designed specifically for process industries, offering specialized tools for managing production, quality, and compliance.

Use Case: Best for companies in the food and beverage, chemical, and pharmaceutical industries.

Pros:

- Industry-specific features and tools.

- Cloud-based with strong scalability.

- Comprehensive support for compliance.

Cons:

- May require industry-specific customization.

- Pricing can be high for smaller enterprises.

Price: Contact Infor for detailed pricing information.

Where to Buy: Infor CloudSuite Process Manufacturing – Visit Infor’s website for more details and a demo.

5. Epicor ERP

Insert image of Epicor ERP.

Epicor ERP offers flexible solutions tailored to various manufacturing sectors, including process manufacturing. It features strong supply chain management, production planning, and financial management tools.

Use Case: Suitable for mid-sized to large businesses needing an adaptable and customizable ERP solution.

Pros:

- Highly customizable to fit specific business needs.

- Strong supply chain and production planning features.

- Flexible deployment options.

Cons:

- Implementation can be complex.

- Higher cost for comprehensive solutions.

Price: Pricing details are available upon request.

Where to Buy: Epicor ERP – Visit Epicor’s website to get more information and request a demo.

Choosing the Right Process Manufacturing ERP System

When selecting a process manufacturing ERP system, consider the following factors:

- Business Size and Requirements: Ensure the ERP system aligns with your company’s size and specific needs.

- Budget: Evaluate the cost against your budget and expected ROI.

- Integration Needs: Check how well the ERP system integrates with your existing systems and processes.

- Scalability: Choose a system that can grow with your business.

How to Buy and Where to Buy

To purchase any of these ERP systems, visit the respective product websites to request a demo, get pricing information, or contact sales representatives. Many vendors offer tailored solutions and can provide personalized quotes based on your business requirements.

FAQs

1. What is a process manufacturing ERP system? A process manufacturing ERP system is a software solution designed to manage and integrate various processes in industries where products are created through continuous or batch processes. It helps streamline operations, improve efficiency, and ensure regulatory compliance.

2. How do I choose the right ERP system for my business? Consider factors such as your business size, specific needs, budget, integration requirements, and scalability. Evaluating these aspects will help you select an ERP system that best fits your company’s operations and goals.

3. What are the typical costs associated with implementing an ERP system? Costs can vary widely based on the ERP system’s complexity, the number of users, and the level of customization required. Contact the ERP vendors directly for detailed pricing information and to get a quote tailored to your business needs.